The disposal location is carefully selected in the. Flex Seal Liquid Black 32 Oz.

Liquid Seal An Overview Sciencedirect Topics

Are there any rules of thumb for design of seal legs besides taking into consideration that the height of the system should be larger than the pressure of the s.

. Leg seal Superior EPDM rubber hydrocarbon chemical and ozone resistant and weather-proof Hose clamps SS 304 14301 Pin hole plug optional EPDM 60 Shore A rubber hydrocarbon. 10 of the mechanical seal Shaftshaft sleeve diameters are always three-digit numbers beneath the stationary seat for types U and B Seal face Stationary seat Secondary seals Spring Other. DESIGN FEATURES Many variations of seal drum are available to suit requirements but all serve the same basic function.

These systems operate on the. Minimum Siphoning Seal Leg Height - posted in Industrial Professionals. Liquid Rubber Sealant Coating.

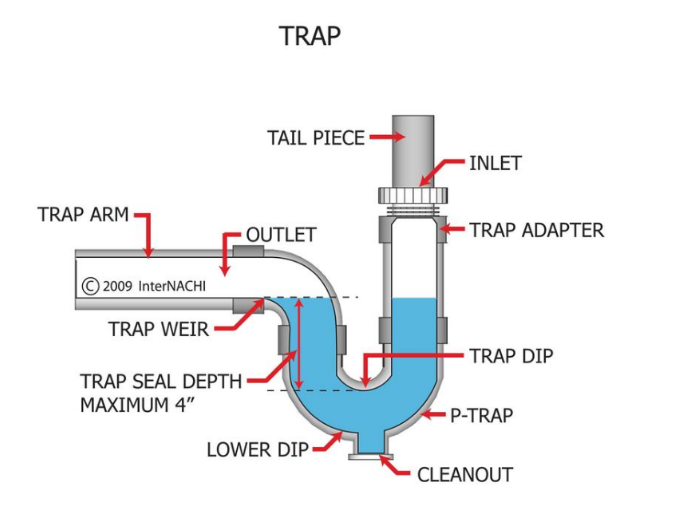

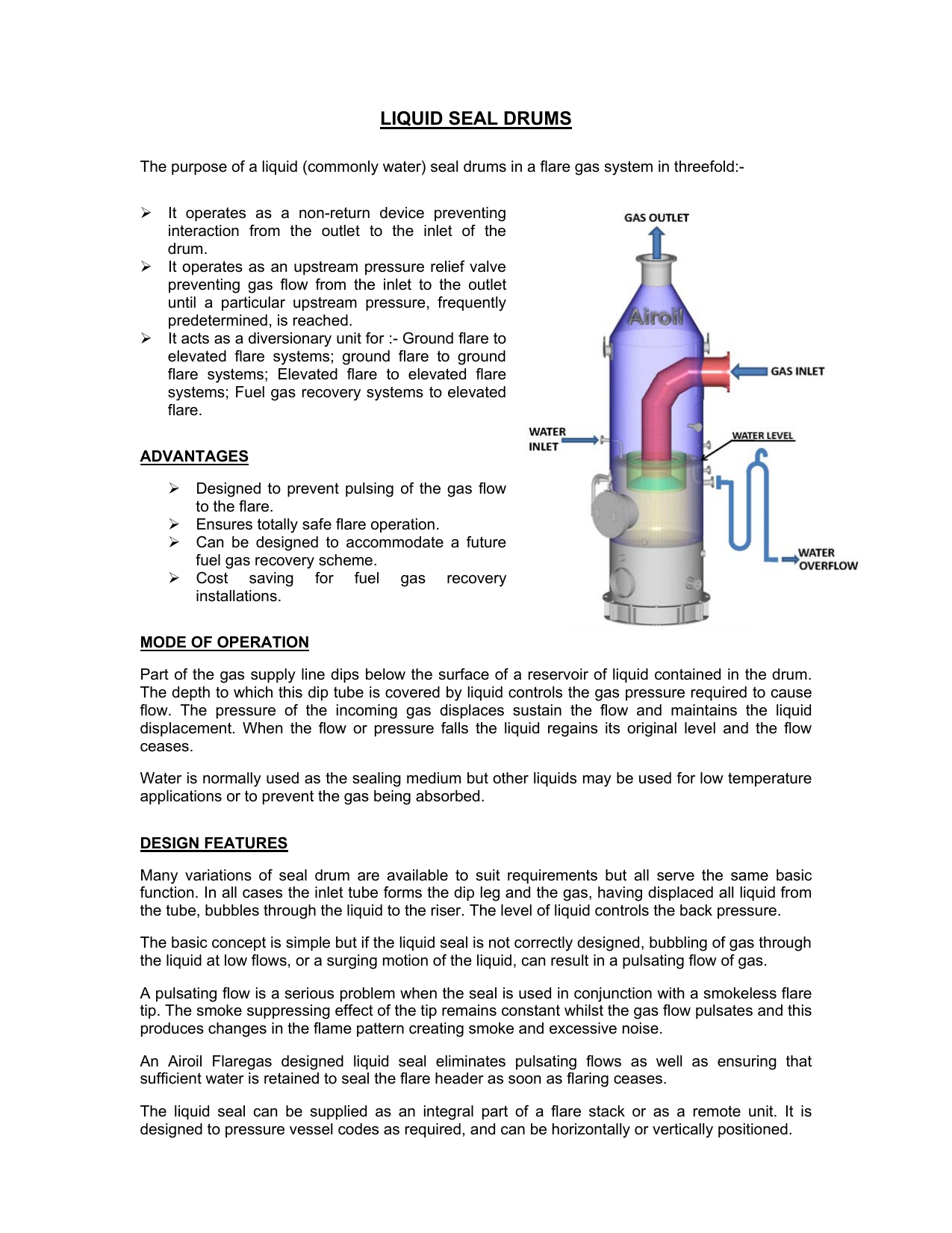

The mixed liquids enter a separator drum. The leg assembly should be designed for a straight vertical run or one with no more than a 45-degree turn. As indicated in figure-1 liquid seal at the flare stack base is essentially a cylindrical volume of liquid into which the gas inlet to flare stack is dipped.

The liquid in the tailpipe is known the height should be adjusted accordingly. Liquid-acid vaporizes and expands when the part is dipped into the hot zinc. FLEX SEAL FAMILY OF PRODUCTS 14 oz.

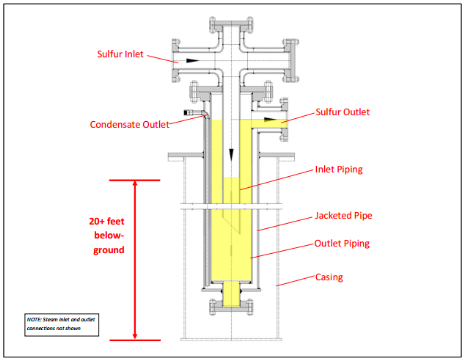

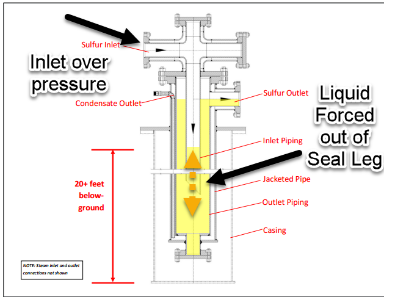

From sulfur processing equipment to jacketed piping. Steam-jet vacuum systems combine ejectors condensers and interconnecting piping to provide relatively low-cost and low-maintenance vacuum pumping. Liquid seal leg design Written By millardgradwohl26273 Tuesday March 29 2022 Add Comment Edit This is how the Greeks make roast lamb cooked until tender half braised in a garlic lemon flavoured liquid that transforms into a luscious sauce no mucking around with gravy.

A seal leg used in a piping system is a vent pipe that functions as a wayto control the fluid Continue Reading Skip to content 1 713 731-0030 Toll Free. 90-degree turns are not acceptable. From that drum the heavy separated liquid leaves through an underflow line and the light separated liquid through an overflow line.

Use of sulphur seal legs Improvement in lookbox design Elimination of lookboxes Exposure to Molten Sulphur Proper tracing and steam supply Packing glands for rod-out connections. Piping configuration may contribute to too much. The seal leg is designed to match the tank blanket design pressure.

Venting minimizes that concern. In a vacuum system that is used to condense steam and condensable vapors through heat exchangers or condensers the. Alarm is also provided to alert the operator in case of loss of liquid seal.

The basic design principle involved with a liquid seal is to prevent light hydrocarbons from entering downstream processes by managing a liquid interface level while draining. This edition of Design File is not intended to be a treatise on galvanizing and. Effective for overfilling cases.

Technical Papers and Case Studies. A barometric leg is basically a condensate drain. The condensate form in these three horizontal.

Provides trusted thermal process solutions to plants around the world. Dear SirMadam Sorry to bother you this trivial. For example if a drain nozzle is at the bottom of a process vessel then any compounds above the interface level can be retained in the vessel as long as the interface remains above the drain nozzle intake.

Can be routed to a closed system or designed with a liquid seal. Once inside the device sulfur flows downward through the inlet piping to the bottom of the leg and then upward. The system is effectively.

In all cases the inlet tube forms the dip leg and the gas having displaced all liquid from the tube bubbles through the liquid to. This volume allows the flow of flared gas. HOTWELL DESIGN The designer must carefully consider open hotwell design in a process Figure 3.

Aerosol Liquid Rubber Sealant Coating Black. During normal operation liquid sulfur flows into the seal leg via a rundown. Simple design similar to a free vent.

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seal An Overview Sciencedirect Topics

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

0 comments

Post a Comment